Artificial Intelligence presents a significant opportunity for business growth, but rising demand intensifies pressure on already stressed global supply chains.

While AI chip manufacturers race to meet market needs, they face an increasingly complex web of risk factors, regulatory requirements, and significant operational challenges that all demand sophisticated approaches to third-party risk management.

Over the long term, a cohesive risk management strategy can give businesses a significant competitive edge. By embedding proactive risk management into their operations, companies can overcome the risk of supply chain disruptions, stay ahead of regulatory changes, and ultimately position themselves to lead in this growing market.

A Global Web of Chip Manufacturing

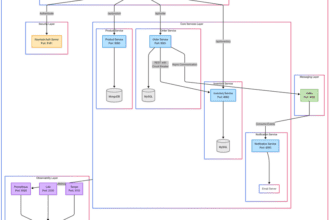

The semiconductor supply chain represents one of the industry’s most intricate and globally distributed manufacturing processes. From raw silicon extraction to final testing, each chip passes through multiple countries and specialized facilities, forming a complex network of interdependencies and potential failure points.

Production begins with silicon wafers, which are predominantly produced in East Asia. These wafers then travel to fabrication plants with advanced machinery sourced from Germany, Japan, and the United States. The final stages involve testing and packaging at Outsourced Semiconductor Assembly and Test (OSAT) facilities, most of which are in Asia.

The fragmented nature of semiconductor production poses significant challenges for supplier risk management. Beyond the risk posed by delays in delivery or production, which can disrupt operations, such a globalized and complex supply chain poses challenges from a regulatory angle. C chipmakers must take full responsibility for ensuring compliance at every level by thoroughly monitoring and vetting every entity in the supply chain for risks such as forced labor, sanctions violations, bribery, and corruption.

Over the past 10 years, firms have had to adapt to new compliance regulations focused on Tier N suppliers operating several layers deep within the supply chain. Key legislation, such as the U.K.’s 2015 Modern Slavery Act, Germany’s 2023 Due Diligence Act, and the 2018 U.S.-Mexico-Canada Agreement (USMCA, has placed greater emphasis on firms to ensure their entire supply chain adheres to labor standards. This increased scrutiny is also relevant for businesses operating in the U.K., which hosted 29% of European modern slavery incidents in 2023, according to data from Moody’s.

Responding to New Export Control Requirements

Introducing new export control requirements affecting emerging technologies, including AI chips and semiconductors, presents an additional challenge for chip manufacturers. On March 12, 2024, the U.K. Export Control Joint Unit announced updates to the U.K.’s export control regime, including new restrictions on semiconductor technologies, reflecting a broader global trend towards protecting sovereign technology in emerging sectors. The European Union is similarly advancing its semiconductor strategy with stricter controls on technology exports. At the same time, the United States recently announced additional export controls on AI chips and technologies to dozens of countries.

Navigating these requirements will require a compliance infrastructure capable of monitoring and responding to evolving regulations for firms operating in the U.K., EU, and U.S. Beyond managing inward supply chains, companies must also implement tools to thoroughly vet the entities they do business with to ensure complete compliance across operations. These measures are key for firms to mitigate risks, turn regulatory challenges into opportunities for differentiation, build trust with stakeholders, and secure their position in the global semiconductor value chain.

Adapting to regulation, risk, and disruption, AI chip manufacturers increasingly use advanced risk management solutions to address these challenges. Automated monitoring tools now support companies to map risk profiles based on factors ranging from human rights violations to jurisdictional compliance issues. These systems provide near real-time visibility into key supplier-related risk factors and potential disruptions, enabling proactive responses to emerging challenges before they escalate.

Many companies are diversifying their supplier base, increasing local procurement efforts, and using predictive modeling to anticipate better demand to address the risk of disruption triggered by delays in delivery or operations. By leveraging advanced data analytics and securing multiple supply routes, businesses can better increase resilience to external shocks and mitigate the risk of supply chain delays.

Additionally, firms can incorporate a “value at risk” model into supply chain and operational risk management frameworks. This approach quantifies the financial impact of potential supply chain disruptions, helping chipmakers prioritize the most critical risk areas. By focusing on areas with the highest potential impact, chipmakers can allocate resources more efficiently, ensuring more effective compliance and operational resilience.

Building Resilience Through Advanced Risk Management

The AI chip supply chain is a cornerstone of modern innovation, but due to its global and interdependent nature, it is inherently complex. With demand for AI technologies expected to grow, firms must adapt and find ways to navigate these complexities to compete in the market. Heightened geopolitical tensions, stringent regulatory frameworks, and operational risks demand a proactive and strategic approach.

To build resilience against key challenges, companies must invest in advanced data and risk management tools, diversify their supplier networks, and harness the power of predictive analytics. Such measures better safeguard supply chain continuity and enhance compliance and operational efficiency. By proactively addressing risks and demonstrating adaptability, businesses can strengthen stakeholder trust and solidify their place in the evolving semiconductor value chain.

The post Navigating Supply Chain Risk in AI chips appeared first on The New Stack.